USING ONLY QUALITY MATERIALS:

For the best product, the best material.

We use the best combination of alloys for your product and run tests to meet your requirements.

Copper

Steel/Stainless Steel

Brass

Aluminum

Zinc - ZAMAK

Zinc alloy characteristics:

-

High strength and hardness

-

Excellent electrical conductivity

-

High thermal conductivity

-

High dimensional accuracy/stability

-

Excellent thin wall capability

-

High quality finishing characteristics

-

Outstanding corrosion resistance

-

100% recyclable

Types of Plastic

-

Polyethylene terephthalate (PET)

-

High-density polyethylene (HDPE)

-

Polyvinyl chloride (PVC)

-

Low-density polyethylene (LDPE)

-

Polypropylene (PP)

-

ABS (Acrylonitrile Butadiene Styrene)

-

Nylon

Zamak 2

has the same composition as zamak 3 with the addition of 3% copper in order to increase strength by 20%, which also increases the price. Zamak 2 has the greatest strength out of all the zamak alloys. Over time it retains its strength and hardness better than the other alloys; however, it becomes more brittle, shrinks, and less elastic.

Zamak 3

is the de facto standard for the zamak series of zinc alloys; all other zinc alloys are compared to this. Zamak 3 has the base composition for the zamak alloys (96% zinc, 4% aluminium). It has excellent castability and long term dimensional stability. More than 70% of all North American zinc die castings are made from zamak 3.

Zamak 4

was developed for the Asian markets to reduce the effects of die soldering while maintaining the ductility of zamak 3. This was achieved by using half the amount of copper from the zamak 5 composition.

Zamak 5

has the same composition as zamak 3 with the addition of 1% copper in order to increase strength (by approximately 10%), hardness and corrosive resistance, but reduces ductility. It also has less dimensional accuracy. Zamak 5 is more commonly used in Europe.

Zamak 7

has less magnesium than zamak 3 to increase fluidity and ductility, which is especially useful when casting thin wall components. In order to reduce inter-granular corrosion a small amount of nickel is added and impurities are more strictly controlled.[

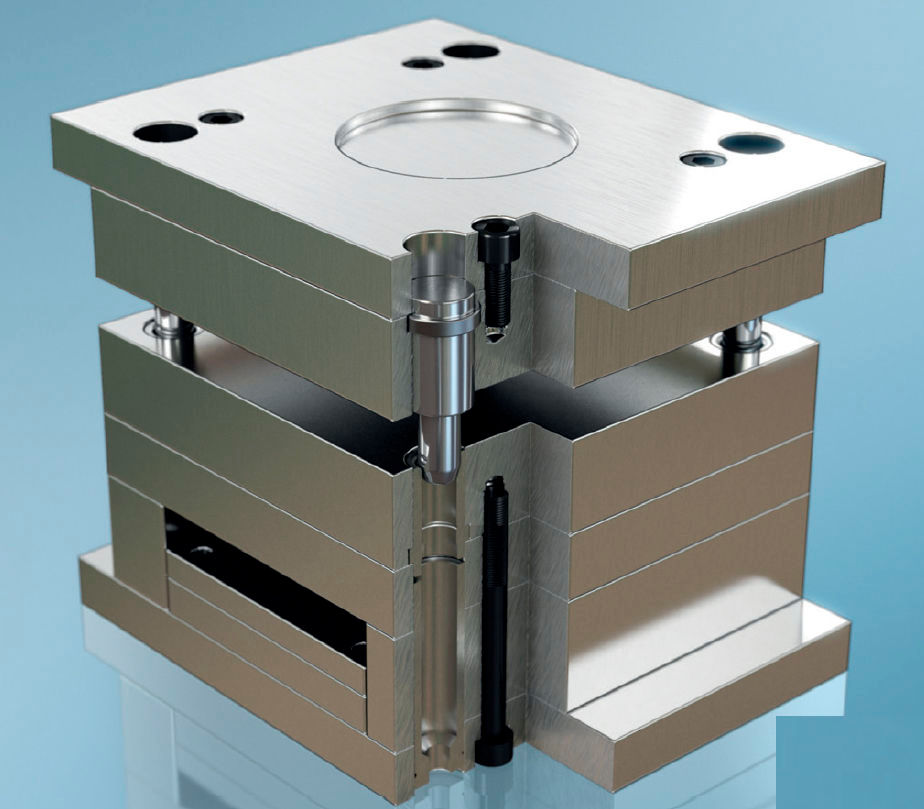

YOUR CUSTOM MOLD